18 April 2024

Hazardous Substances AS1940 Flammable Liquids Cabinets – what has changed?

Our hazardous substances consultant Alex Marquand-Gray has written this short piece on the changes outlined in the technical bulletin issued by WorkSafe relating to...18 April 2024

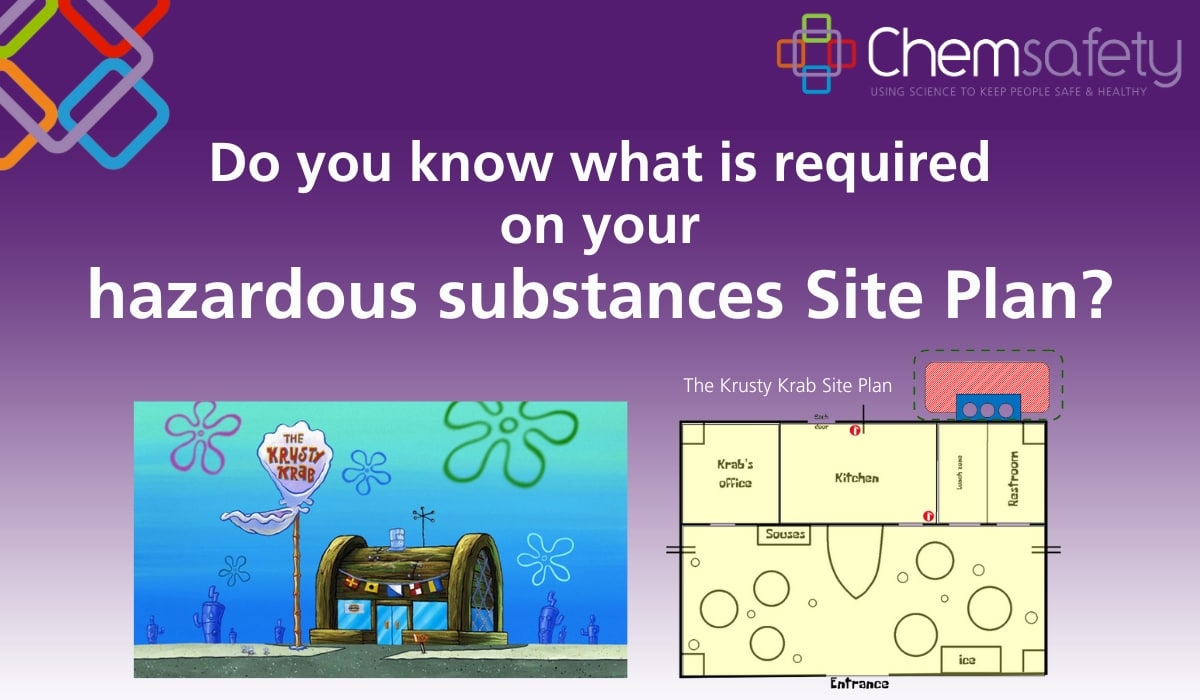

What is required on your hazardous substances Site Plan

Our hazardous substances consultant Mackenzie Cox has written this short piece outlining what is required on your hazardous substances Site Plan....18 April 2024

Upcoming changes to IANZ accreditation regarding the use of wipe and tape samples for asbestos identification

In this article written by our Lab Manager Livia Fioravanti, we want to bring to your attention the latest update IANZ has made to...23 February 2024

February 2024 Newsletter

Welcome to our first newsletter for 2024. We let you know how to get 10% discount if you are attending the Health & Safety...21 February 2024

What you need to know when the Workplace Exposure Standards are lowered

In this webinar we discuss how the Workplace Exposure Standards are frequently being lowered making it more difficult for businesses to comply with the...12 February 2024

Updated Workplace Exposure Standards and Biological Exposure Indices now available

WorkSafe have released the 14th edition of the Workplace Exposure Standards and Biological Exposure Indices, or the new WES for short. This is one...30 January 2024

EPA Submissions on changes to rules for lead levels in paints

The Environmental Protection Agency (EPA) is currently consulting on proposals to cut the levels of lead permitted in paints and graphic materials - especially...15 December 2023

December 2023 Newsletter

Welcome to our last newsletter for 2023 that lets you know our holiday close down dates, who in our team is the recipient of...27 October 2023

October 2023 Newsletter

Take a look at our October 2023 newsletter. We have some great articles on how the EPA proposed infringement notices will affect agricultural operations,...26 October 2023

Exposure Monitoring in the Construction Industry Webinar

Join our Senior Occupational Hygienist Almi for our webinar on Exposure Monitoring in the Construction Industry. Learn more about how to identify and address...25 October 2023

EPA & workplace only hazardous substances

Janet Connochie our Senior Hazardous Substances Consultant, Compliance Certifier and Director has written this piece on the Hazardous Substances (Hazardous Property Controls) Notice that includes...19 October 2023

EPA proposed infringement notices effect on agricultural operations

We look at the proposed EPA Infringement Notice Scheme and outline the main infringement notices that could effect agricultural operations....24 August 2023

Navigating Compliance Certifier Scopes Webinar

In this webinar we discuss how to find the correct Compliance Certifier for your requirements by using the WorkSafe Register of Compliance Certifiers and...18 August 2023

August 2023 Newsletter

Take a look at our August 2023 newsletter where we congratulate another one of our team on their 10 year anniversary. We also discuss...03 August 2023

Hazardous Substances Infringement Notices – EPA Consultation

Our Senior Hazardous Substances Consultant and Director Janet Connochie has written this short piece on the proposed implementation of a hazardous substances infringement scheme...22 June 2023

Indoor Air Quality & Ventilation Webinar

Join our Senior Occupational Hygienist Almi Bradfield-van Wyk for our June free online webinar on Indoor Air Quality and Ventilation. Learn more about how...15 June 2023

June 2023 Newsletter

Take a look at our mid-year June 2023 newsletter where we congratulate one of our team on their 10 year anniversary. We also discuss...02 May 2023

Notification of refusal to issue a compliance certificate

Janet Connochie has written this piece on the updated performance standard which came into force on 1 May 2023, and this now specifies that...20 April 2023

April 2023 Newsletter

In our April 2023 newsletter we introduce you to our latest team member based in Wellington, and also let you know about a special...30 March 2023

The importance of good lighting

A fantastic piece on the importance of good lighting and why it's essential to illuminate correctly for the type of work being done....28 March 2023

Asbestos Types & the Risks to Health

Asbestos is a group of naturally occurring minerals made up of many small fibres. There are 6 types of asbestos that belong to the...24 March 2023

Bridgette Jennings – A reflection on 20 years

Bridgette Jennings looks back on her time with Chemsafety in this final reflection on her 20 years....23 March 2023

Making the most of your Emergency Response Plan testing Webinar

In this webinar our presenter Janet Connochie examines what is needed in an Emergency Response Plan for hazardous substances, how you can improve your...28 February 2023

Flooring Materials & Asbestos

In the past, vinyl manufacturers often mixed asbestos fibres into their products for greater strength and insulating properties. Construction companies also favoured asbestos-containing materials...28 February 2023

Asbestos ID Test – Types of Fibres That Can Be Reported

One of the frequently asked questions from our clients when they receive the results for the asbestos identification test, is what does the presence...28 February 2023

Plaster Materials & Their Relationship with Asbestos

Plaster material used for coating walls, ceilings and partitions is the most common building material received by Chemsafety’s Laboratory for asbestos identification. After...24 February 2023

Mould – what you need to know

Due to the recent devastation caused by Cyclone Gabrielle in New Zealand, this is a timely reminder of the hazards that mould can cause...22 February 2023

Asbestos for Managers Webinar

In this webinar, we discuss what project managers need to know to protect themselves and their teams from exposure. We cover best practices for...16 February 2023

February 2023 Newsletter

In our first newsletter for 2023 we let you know how the move to our new Wellington office is going, the recent award we...13 December 2022

December 2022 Newsletter

In our final newsletter for 2022 we show why you need to save the date for a great upcoming conference in 2023. We also...24 November 2022

Worker Training & Certified Handlers Webinar

In this webinar, we cover the intricacies of what needs to be covered as per Part 4.5 of HSW(HS) and when refresher training should...18 October 2022

October 2022 Newsletter

In our October 2022 Newsletter we have some exciting updates about our stand at HASANZ and discuss Ethanedinitrile, the new fumigant that has been...22 September 2022

Managing Solvent Exposure in the Workplace Webinar

In this webinar, we look into the solvents found and used in workplaces, discuss their associated health effects and look at controls we can...21 September 2022

Mould & the Impacts on Health Webinar

Mould is widespread in the environment but certain types, or elevated levels of mould, can cause significant health impacts. ...11 September 2022

Accidentally exposed to Asbestos in your home?

After our last Webinar on Asbestos Contamination Options, one of the most asked questions was what to do if you have been accidentally exposed...25 August 2022

Asbestos Contamination Options Webinar

In this free online webinar our Senior Asbestos Consultant Tony Bird will be discussing what signs to look for and what you need to...18 August 2022

August 2022 Newsletter

In our August 2022 Newsletter we are excited to tell you about our new Wellington office. We also let you know about our next...18 August 2022

Hazardous Substances Non-Compliance Trends In The Healthcare Sector

Sara Aldridge has put together this blog discussing hazardous substances non-compliance trends in the health care sector....28 July 2022

Common findings relating to hazardous substances in the health care sector webinar

Following multiple audits over recent years relating to hazardous substances compliance across various health care providers, our Senior Hazardous Substances Consultant and Compliance Certifier...16 June 2022

June 2022 Newsletter

In our June 2022 Newsletter we let you know about two serious WorkSafe incidents. We also let you know about our next two free...15 June 2022

Why keeping your respirator clean is important

Why keeping your respirator clean is important...15 June 2022

Introducing our new Website

It’s not everyday you get to launch a new website and we decided this was a great time to do it and we are...26 May 2022

What signage do you need for Hazardous Substances?

Join Senior Consultant Elizabeth Harwood for our online webinar as she discusses hazardous substance signage. She will examine what the regulatory requirements are and...27 April 2022

Understanding & Managing Workplace Noise Control Options

Join our Occupational Hygiene Team Leader and Senior Consultant Sam McGee as he introduces you to some of the noise control options available in...04 April 2022

April 2022 Newsletter

In our April 2022 Newsletter we help ease you in to the new Performance Standards and have a look at the changes to the...24 March 2022

Controlling Human Vibration Hazards in the Workplace

Join Wellington Occupational Hygienist Christine de Klerk who will give an overview of both hand-arm vibration (HAV) and whole-body vibration (WBV). ...05 March 2022

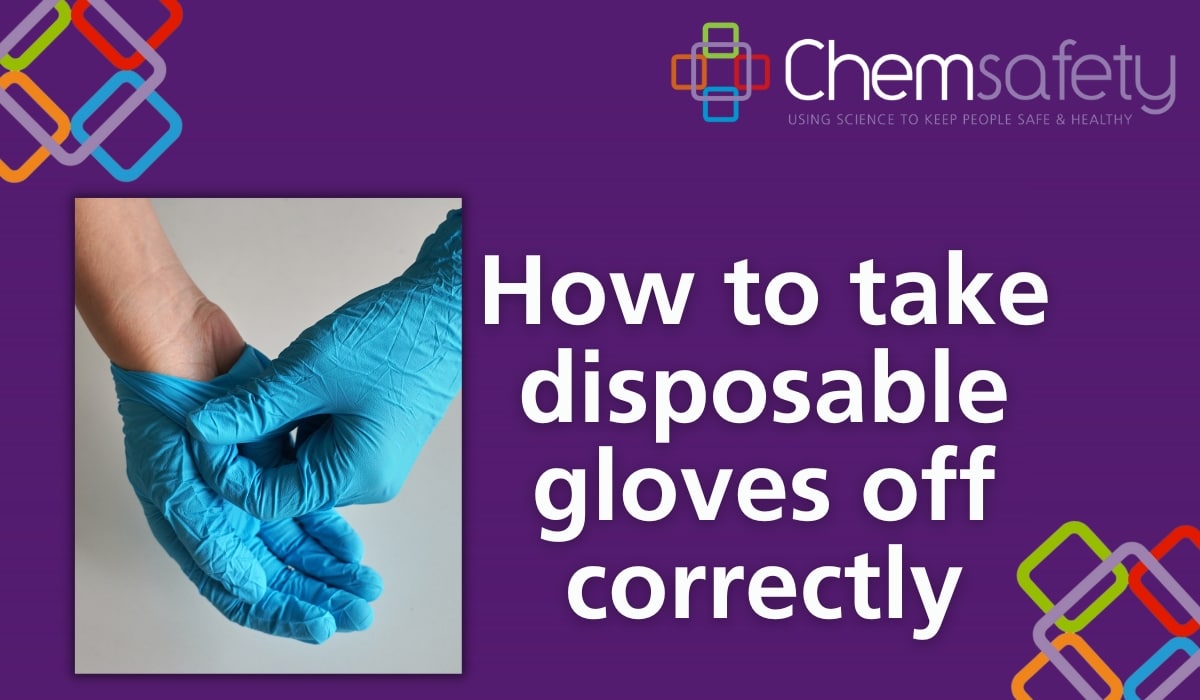

How To Take Disposable Gloves Off Correctly

It is important to know how to remove gloves properly, as improper removal can lead to transfer of contaminants from your gloves to your...24 February 2022

Understanding the H&S at Work (Haz Subs) Amendment Regulations 2021

Towards the end of last year the long awaited Health and Safety at Work (Hazardous Substances) Amendment Regulations were released (they came into force...17 February 2022

Chemsafety’s HASANZ 2021 Scholarship Recipients

We are proud to announce that three of Chemsafety’s employees have recently been awarded Health and Safety New Zealand (HASANZ) Scholarships for 2021!...02 February 2022

February 2022 Newsletter

In our first newsletter for 2022 we introduce you to our HASANZ Scholarship Award recipients, let you know about the first free online webinars...21 October 2021

5 Common Reasons a Clearance Inspection fails

5 common reasons a clearance inspection following asbestos removal fails...06 October 2021

Respiratory Protection Program

Respirators (dust masks, half face masks etc.) are a common tool for controlling exposure to dusts and chemicals. ...22 September 2021

The Different Types of Asbestos Surveys

Join our Senior Asbestos Consultant Tony Bird where he outlines the different types of Asbestos Surveys and which one is right for your property,...18 August 2021

LCC – Avoiding Non-Compliances

Do you want to know what the common non-compliances are that hold up companies from getting their location compliance certification on time?...20 July 2021

Hierarchy of Controls

Join our Occupational Hygiene Team Leader Sam McGee to learn about how the Hierarchy of Controls is used to control hazards in the workplace....20 May 2021

Why All Workplace Dusts Are Not Equal

Why all workplace dusts are not equal?......18 May 2021

Explaining Asbestos Identification Analysis

We explain in a short and simple way how the identification of asbestos in building materials is done....13 May 2021

Worker Training for Hazardous Substances

Are you unsure of what training is required for hazardous substances? Join Chemsafety’s webinar to find out what training is required and for who,...06 May 2021

What Is An Occupational Hygienist?

They are not workplace cleaners or occupational health nurses. Occupational Hygienists anticipate, recognise, evaluate and control biological, physical, and chemical......05 May 2021

Why Class 5 Hearing Protection Can Over Protect Your Workers

Do you know why Class 5 hearing protection can over protect your workers and the consequences over protection?Read our article......30 April 2021

Its GHS Time

Today is the 30 April 2021 – its GHS time!Well the time has finally arrived, from today New Zealand has......28 April 2021

Asbestos In Your Home

Was your house built before 2000? Find out what you need to do as a homeowner when completing renovations of......15 April 2021

GHS Classification Changes

On 30 April 2021 New Zealand adopted the GHS classification system in place of the HSNO classification system that we have been using for...06 April 2021

5 Reasons you shouldn’t collect your own asbestos samples

Taking an asbestos sample doesn't look particularly tricky but there are reasons why you should leave it to the experts.......28 October 2020

Class 6 & 8 Hazardous Substances

Hazardous substance classifications 6 & 8 are treated differently in the Regulations. In this free online webinar learn what substances are included in these...14 October 2020

PCBU Obligations

In this free webinar we ask - as a PCBU do you know exactly what your obligations are in regards to hazardous substances?...08 October 2020

Shielding your workers from silica dust, asbestos & other environmental contaminants

As part of the Safety 360 Conference back in 2020 our Senior Occupational Hygiene Consultant and Team Leader, Sam McGee put together this webinar...30 September 2020

What you need to know about exposure monitoring

Do you know what to look for within your exposure monitoring programme? ...09 September 2020

What should be in a Hazardous Substance Site Plan

In this free online webinar you will be shown that if you have hazardous substances on your site you should have a site plan...26 August 2020

How to Label Chemicals you decant

Do you take chemicals from large containers and put them into a smaller more usable container? ...12 August 2020

Minimising Exposure to Hazardous Substances

Hazardous substances are not just chemicals, dust, fumes and workplace equipment and processes can also cause us harm. ...29 July 2020

Emergency Response Spills & Leaks

In this free online webinar we ask do you know what to do if the hazardous substances you use and store begin to spill...17 June 2020

What are Incompatible Substances

Have you ever wondered why the mixture of certain substances can cause fires, fumes and explosive effects?...10 June 2020

Keeping Track of your Hazardous Substances

This webinar looks at the information you need to keep regarding the hazardous substances on site. ...22 May 2020

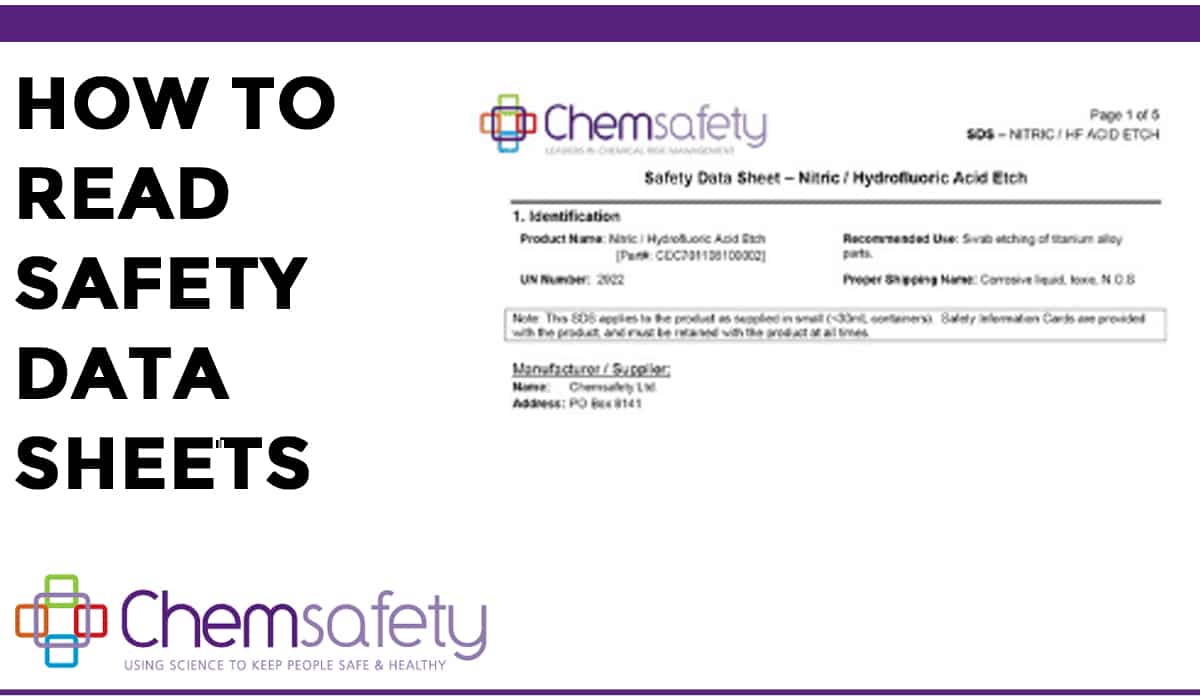

How to read Safety Data Sheets

This webinar covers the intricacies of the Material Safety Data Sheet, or SDS for short. ...20 May 2020

Hazardous Substance Classifications

We begin this webinar with a brief description of what a hazardous substance is as defined by the EPA’s Hazardous Substances (Minimum Degree of...18 December 2019

December 2019 Newsletter

Happy holidays everyone, the Christmas season is upon us again and as another year draws to a close its a great time to reflect...10 October 2019

October 2019 Newsletter

We're incredibly excited to announce that Chemsafety now has a in-house asbestos analysis laboratory which is accredited through IANZ....12 December 2018

December 2018 Newsletter

2018 is quickly coming to close and it's been another busy year at Chemsafety. We've experience more growth in our business and as...06 June 2018

June 2018 Newsletter

We're really excited to annouce that Chemsafety has opened a new office in Wellington. The Wellington Office at 12 Cruickshank Street in...11 November 2016

November 2016 Newsletter

Christmas is fast approaching again! It's been another busy year at Chemsafety and we're looking forward to a relaxing break over Christmas and...10 October 2016

October 2016 Newsletter

We're excited to announce that the Chemsafety family has expanded since our last newsletter. ...05 May 2016

May 2016 Newsletter

The new Health and Safety at Work Act came into force on 4 April 2016 and this has meant some of our clients have...18 April 2024

Upcoming changes to IANZ accreditation regarding the use of wipe and tape samples for asbestos identification

In this article written by our Lab Manager Livia Fioravanti, we want to bring to your attention the latest update IANZ has made to...28 March 2023

Asbestos Types & the Risks to Health

Asbestos is a group of naturally occurring minerals made up of many small fibres. There are 6 types of asbestos that belong to the...28 February 2023

Flooring Materials & Asbestos

In the past, vinyl manufacturers often mixed asbestos fibres into their products for greater strength and insulating properties. Construction companies also favoured asbestos-containing materials...28 February 2023

Plaster Materials & Their Relationship with Asbestos

Plaster material used for coating walls, ceilings and partitions is the most common building material received by Chemsafety’s Laboratory for asbestos identification. After...11 September 2022

Accidentally exposed to Asbestos in your home?

After our last Webinar on Asbestos Contamination Options, one of the most asked questions was what to do if you have been accidentally exposed...21 October 2021

5 Common Reasons a Clearance Inspection fails

5 common reasons a clearance inspection following asbestos removal fails...18 May 2021

Explaining Asbestos Identification Analysis

We explain in a short and simple way how the identification of asbestos in building materials is done....28 April 2021

Asbestos In Your Home

Was your house built before 2000? Find out what you need to do as a homeowner when completing renovations of......06 April 2021

5 Reasons you shouldn’t collect your own asbestos samples

Taking an asbestos sample doesn't look particularly tricky but there are reasons why you should leave it to the experts.......18 April 2024

Hazardous Substances AS1940 Flammable Liquids Cabinets – what has changed?

Our hazardous substances consultant Alex Marquand-Gray has written this short piece on the changes outlined in the technical bulletin issued by WorkSafe relating to...18 April 2024

What is required on your hazardous substances Site Plan

Our hazardous substances consultant Mackenzie Cox has written this short piece outlining what is required on your hazardous substances Site Plan....30 January 2024

EPA Submissions on changes to rules for lead levels in paints

The Environmental Protection Agency (EPA) is currently consulting on proposals to cut the levels of lead permitted in paints and graphic materials - especially...25 October 2023

EPA & workplace only hazardous substances

Janet Connochie our Senior Hazardous Substances Consultant, Compliance Certifier and Director has written this piece on the Hazardous Substances (Hazardous Property Controls) Notice that includes...19 October 2023

EPA proposed infringement notices effect on agricultural operations

We look at the proposed EPA Infringement Notice Scheme and outline the main infringement notices that could effect agricultural operations....03 August 2023

Hazardous Substances Infringement Notices – EPA Consultation

Our Senior Hazardous Substances Consultant and Director Janet Connochie has written this short piece on the proposed implementation of a hazardous substances infringement scheme...02 May 2023

Notification of refusal to issue a compliance certificate

Janet Connochie has written this piece on the updated performance standard which came into force on 1 May 2023, and this now specifies that...18 August 2022

Hazardous Substances Non-Compliance Trends In The Healthcare Sector

Sara Aldridge has put together this blog discussing hazardous substances non-compliance trends in the health care sector....30 April 2021

Its GHS Time

Today is the 30 April 2021 – its GHS time!Well the time has finally arrived, from today New Zealand has......19 April 2024

April 2024 Newsletter

Welcome to our Autumn newsletter for 2024. In this edition we discuss the upcoming changes to IANZ accreditation, what has changed in hazardous substances...23 February 2024

February 2024 Newsletter

Welcome to our first newsletter for 2024. We let you know how to get 10% discount if you are attending the Health & Safety...15 December 2023

December 2023 Newsletter

Welcome to our last newsletter for 2023 that lets you know our holiday close down dates, who in our team is the recipient of...27 October 2023

October 2023 Newsletter

Take a look at our October 2023 newsletter. We have some great articles on how the EPA proposed infringement notices will affect agricultural operations,...18 August 2023

August 2023 Newsletter

Take a look at our August 2023 newsletter where we congratulate another one of our team on their 10 year anniversary. We also discuss...15 June 2023

June 2023 Newsletter

Take a look at our mid-year June 2023 newsletter where we congratulate one of our team on their 10 year anniversary. We also discuss...20 April 2023

April 2023 Newsletter

In our April 2023 newsletter we introduce you to our latest team member based in Wellington, and also let you know about a special...16 February 2023

February 2023 Newsletter

In our first newsletter for 2023 we let you know how the move to our new Wellington office is going, the recent award we...13 December 2022

December 2022 Newsletter

In our final newsletter for 2022 we show why you need to save the date for a great upcoming conference in 2023. We also...18 October 2022

October 2022 Newsletter

In our October 2022 Newsletter we have some exciting updates about our stand at HASANZ and discuss Ethanedinitrile, the new fumigant that has been...18 August 2022

August 2022 Newsletter

In our August 2022 Newsletter we are excited to tell you about our new Wellington office. We also let you know about our next...16 June 2022

June 2022 Newsletter

In our June 2022 Newsletter we let you know about two serious WorkSafe incidents. We also let you know about our next two free...04 April 2022

April 2022 Newsletter

In our April 2022 Newsletter we help ease you in to the new Performance Standards and have a look at the changes to the...02 February 2022

February 2022 Newsletter

In our first newsletter for 2022 we introduce you to our HASANZ Scholarship Award recipients, let you know about the first free online webinars...18 December 2019

December 2019 Newsletter

Happy holidays everyone, the Christmas season is upon us again and as another year draws to a close its a great time to reflect...10 October 2019

October 2019 Newsletter

We're incredibly excited to announce that Chemsafety now has a in-house asbestos analysis laboratory which is accredited through IANZ....12 December 2018

December 2018 Newsletter

2018 is quickly coming to close and it's been another busy year at Chemsafety. We've experience more growth in our business and as...06 June 2018

June 2018 Newsletter

We're really excited to annouce that Chemsafety has opened a new office in Wellington. The Wellington Office at 12 Cruickshank Street in...11 November 2016

November 2016 Newsletter

Christmas is fast approaching again! It's been another busy year at Chemsafety and we're looking forward to a relaxing break over Christmas and...10 October 2016

October 2016 Newsletter

We're excited to announce that the Chemsafety family has expanded since our last newsletter. ...05 May 2016

May 2016 Newsletter

The new Health and Safety at Work Act came into force on 4 April 2016 and this has meant some of our clients have...21 February 2024

What you need to know when the Workplace Exposure Standards are lowered

In this webinar we discuss how the Workplace Exposure Standards are frequently being lowered making it more difficult for businesses to comply with the...12 February 2024

Updated Workplace Exposure Standards and Biological Exposure Indices now available

WorkSafe have released the 14th edition of the Workplace Exposure Standards and Biological Exposure Indices, or the new WES for short. This is one...30 March 2023

The importance of good lighting

A fantastic piece on the importance of good lighting and why it's essential to illuminate correctly for the type of work being done....28 February 2023

Asbestos ID Test – Types of Fibres That Can Be Reported

One of the frequently asked questions from our clients when they receive the results for the asbestos identification test, is what does the presence...24 February 2023

Mould – what you need to know

Due to the recent devastation caused by Cyclone Gabrielle in New Zealand, this is a timely reminder of the hazards that mould can cause...15 June 2022

Why keeping your respirator clean is important

Why keeping your respirator clean is important...17 February 2022

Chemsafety’s HASANZ 2021 Scholarship Recipients

We are proud to announce that three of Chemsafety’s employees have recently been awarded Health and Safety New Zealand (HASANZ) Scholarships for 2021!...20 May 2021

Why All Workplace Dusts Are Not Equal

Why all workplace dusts are not equal?......05 May 2021

Why Class 5 Hearing Protection Can Over Protect Your Workers

Do you know why Class 5 hearing protection can over protect your workers and the consequences over protection?Read our article......21 February 2024

What you need to know when the Workplace Exposure Standards are lowered

In this webinar we discuss how the Workplace Exposure Standards are frequently being lowered making it more difficult for businesses to comply with the...26 October 2023

Exposure Monitoring in the Construction Industry Webinar

Join our Senior Occupational Hygienist Almi for our webinar on Exposure Monitoring in the Construction Industry. Learn more about how to identify and address...24 August 2023

Navigating Compliance Certifier Scopes Webinar

In this webinar we discuss how to find the correct Compliance Certifier for your requirements by using the WorkSafe Register of Compliance Certifiers and...22 June 2023

Indoor Air Quality & Ventilation Webinar

Join our Senior Occupational Hygienist Almi Bradfield-van Wyk for our June free online webinar on Indoor Air Quality and Ventilation. Learn more about how...23 March 2023

Making the most of your Emergency Response Plan testing Webinar

In this webinar our presenter Janet Connochie examines what is needed in an Emergency Response Plan for hazardous substances, how you can improve your...22 February 2023

Asbestos for Managers Webinar

In this webinar, we discuss what project managers need to know to protect themselves and their teams from exposure. We cover best practices for...24 November 2022

Worker Training & Certified Handlers Webinar

In this webinar, we cover the intricacies of what needs to be covered as per Part 4.5 of HSW(HS) and when refresher training should...22 September 2022

Managing Solvent Exposure in the Workplace Webinar

In this webinar, we look into the solvents found and used in workplaces, discuss their associated health effects and look at controls we can...21 September 2022

Mould & the Impacts on Health Webinar

Mould is widespread in the environment but certain types, or elevated levels of mould, can cause significant health impacts. ...25 August 2022

Asbestos Contamination Options Webinar

In this free online webinar our Senior Asbestos Consultant Tony Bird will be discussing what signs to look for and what you need to...28 July 2022

Common findings relating to hazardous substances in the health care sector webinar

Following multiple audits over recent years relating to hazardous substances compliance across various health care providers, our Senior Hazardous Substances Consultant and Compliance Certifier...26 May 2022

What signage do you need for Hazardous Substances?

Join Senior Consultant Elizabeth Harwood for our online webinar as she discusses hazardous substance signage. She will examine what the regulatory requirements are and...27 April 2022

Understanding & Managing Workplace Noise Control Options

Join our Occupational Hygiene Team Leader and Senior Consultant Sam McGee as he introduces you to some of the noise control options available in...24 March 2022

Controlling Human Vibration Hazards in the Workplace

Join Wellington Occupational Hygienist Christine de Klerk who will give an overview of both hand-arm vibration (HAV) and whole-body vibration (WBV). ...24 February 2022

Understanding the H&S at Work (Haz Subs) Amendment Regulations 2021

Towards the end of last year the long awaited Health and Safety at Work (Hazardous Substances) Amendment Regulations were released (they came into force...06 October 2021

Respiratory Protection Program

Respirators (dust masks, half face masks etc.) are a common tool for controlling exposure to dusts and chemicals. ...22 September 2021

The Different Types of Asbestos Surveys

Join our Senior Asbestos Consultant Tony Bird where he outlines the different types of Asbestos Surveys and which one is right for your property,...18 August 2021

LCC – Avoiding Non-Compliances

Do you want to know what the common non-compliances are that hold up companies from getting their location compliance certification on time?...20 July 2021

Hierarchy of Controls

Join our Occupational Hygiene Team Leader Sam McGee to learn about how the Hierarchy of Controls is used to control hazards in the workplace....13 May 2021

Worker Training for Hazardous Substances

Are you unsure of what training is required for hazardous substances? Join Chemsafety’s webinar to find out what training is required and for who,...15 April 2021

GHS Classification Changes

On 30 April 2021 New Zealand adopted the GHS classification system in place of the HSNO classification system that we have been using for...28 October 2020

Class 6 & 8 Hazardous Substances

Hazardous substance classifications 6 & 8 are treated differently in the Regulations. In this free online webinar learn what substances are included in these...14 October 2020

PCBU Obligations

In this free webinar we ask - as a PCBU do you know exactly what your obligations are in regards to hazardous substances?...08 October 2020

Shielding your workers from silica dust, asbestos & other environmental contaminants

As part of the Safety 360 Conference back in 2020 our Senior Occupational Hygiene Consultant and Team Leader, Sam McGee put together this webinar...30 September 2020

What you need to know about exposure monitoring

Do you know what to look for within your exposure monitoring programme? ...09 September 2020

What should be in a Hazardous Substance Site Plan

In this free online webinar you will be shown that if you have hazardous substances on your site you should have a site plan...26 August 2020

How to Label Chemicals you decant

Do you take chemicals from large containers and put them into a smaller more usable container? ...12 August 2020

Minimising Exposure to Hazardous Substances

Hazardous substances are not just chemicals, dust, fumes and workplace equipment and processes can also cause us harm. ...29 July 2020

Emergency Response Spills & Leaks

In this free online webinar we ask do you know what to do if the hazardous substances you use and store begin to spill...17 June 2020

What are Incompatible Substances

Have you ever wondered why the mixture of certain substances can cause fires, fumes and explosive effects?...10 June 2020

Keeping Track of your Hazardous Substances

This webinar looks at the information you need to keep regarding the hazardous substances on site. ...22 May 2020

How to read Safety Data Sheets

This webinar covers the intricacies of the Material Safety Data Sheet, or SDS for short. ...20 May 2020