Management of electrical installations in hazardous areas is critical to avoiding the potential ignition of flammable gases and vapours. If you cannot eliminate the need for electrical equipment within the hazardous area, then you (as the PCBU) must provide evidence of the electrical compliance to your location compliance certifier.

Our hazardous substances consultant Alex Marquand-Gray has written this piece outlining what documentation is required for electrical installations in hazardous areas.

- The electrical equipment / installation must be suitable for use in the hazardous area, this is commonly referred to as ‘intrinsically safe’, but there is a range of suitable equipment and other methods of management.

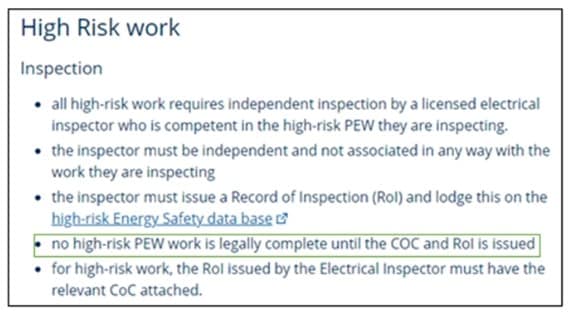

Any prescribed electrical work (this is defined by the Electricity (Safety) Regulations) on an installation that is, or will be, located in a hazardous area is ‘High Risk Prescribed Electrical Work’ (High Risk PEW).

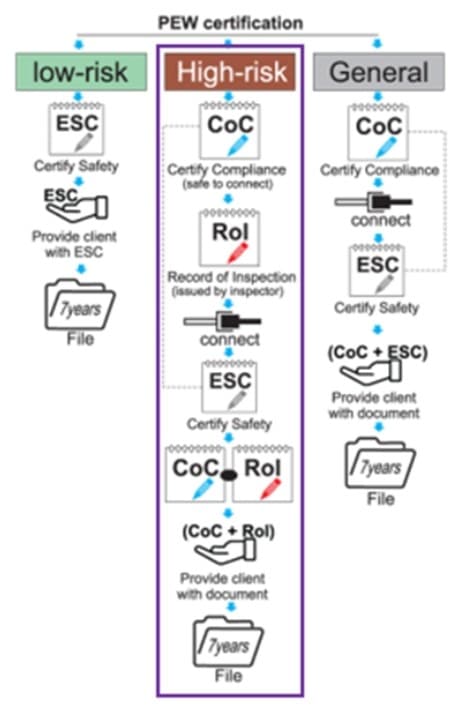

There is a range of documentation required with any electrical work, this is outlined in the following information from the EWRB.

All high-risk work must be inspected, and the record of inspection lodged with the Electricity and Gas High-Risk Database. This requirement has been in place since 1 July 2013.

There is a new framework for Registered and Licensed Electrical Workers starting into effect 1 September 2024, and this includes new endorsements relating specifically to hazardous areas.

Re-inspection

At least every four years hazardous area electrical installations must have a periodic inspection undertaken in accordance with AS/NZS 60079.17:2017 Explosive atmospheres – Part 17: Electrical installations inspection and maintenance. Inspectors can optionally record periodic inspection information in the High Risk Database

In summary, for your location compliance certification for flammable gas or liquid we will need to see

For new installations (less than four years old) or any changes/repairs

- CoC + RoI + ESC

- We may verify entry in the High-Risk Database

For established installations

- Periodic Inspection documentation – Hazardous Area Statement of Periodic Verification

- Including any accompanying report of actions required

Make sure that the documentation is very clear about the scope of the installation covered and talk to your electrical worker if something is missing or not clear. If you are unsure whether the documentation you have or have previously provided is sufficient, please do not hesitate to contact Chemsafety.